Wednesday, October 28, 2015

Tuesday, October 20, 2015

10 minutes of programming can save you thousands of dollars

|

||||

Contact us | +1

617 401 2197 | contact_us@springplm.com

|

Sunday, October 18, 2015

MECT 2015: SPRING Technologies and SAEILO Japan unveil NCSIMUL CAM on the Asia-Pacific market

Rethink your manufacturing process this unique all-in-one solution, streamlining the digital process of CNC machine programming

SPRING Technologies, vendor of software that optimizes the use of NC Machines, will present, with SAEILO Japan, for the 1st time on the Asia-Pacific market, its cutting-edge new module NCSIMUL CAM – part of its new platform NCSIMUL SOLUTIONS 10 -, at the:

MECT tradeshow, hall 3, booth B25, from October 21st to 24th, 2015.

The company's new product delivers agile and native CNC programming to streamline the current serial and iterative CAM process and provides unparalleled flexibility on the shop floor. NCSIMUL CAM directly generates verified and optimized CNC programs, while factoring in the physical resources available on the shop floor, including tools, cutting conditions, kinematics and machine controllers.

NCSIMUL SOLUTIONS V10 is more than just a new version: a technological milestone for manufacturing and production in the aircraft industry– unique and simple to operate. It facilitates a comprehensive, integrated control of the complete machining process, including: G-Code processing, G-code file simulation, Cutting and tool management, DNC G-code file management, Real time machine status monitoring, Technical content publication.

This unique approach, streamlining the complete end-to-end machining process, delivers the tools and flexibility required to build the Factory of the Future.

NCSIMUL CAM directly generates verified and optimized CNC programs, while factoring in the physical resources available on the shop floor, including tools, cutting conditions, kinematics and machine controllers.

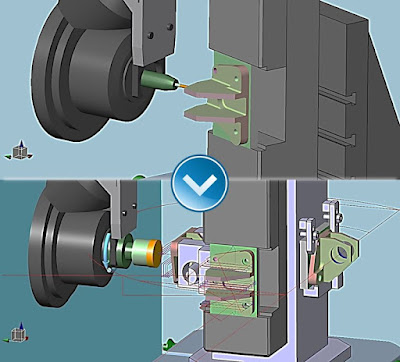

With this new solution, CAM data (APT neutral file / CL-data) and existing CNC programs can be used easily to generate a valid new CNC program in just a few clicks for another machine using different kinematics and controller. This will enable manufacturers to quickly adapt their existing programs to new resources when retrofitting a machine, buying a new one or when a machining process is repurposed. With a conventional CAM process (CAM-Post-Processor-Machining Simulation), this task could take hours, even days. With NCSIMUL CAM, these times are slashed to minutes.

Likewise, if the target machine initially planned for the CAM program is no longer available for maintenance reasons or is already being used to meet production, it will take just one click with NCSIMUL CAM to switch programming to another machine – whatever its complexity (3X to 5X, 5X to 4X…), the type of kinematics (tilting head to table-on-table for instance) or the type of controller (FANUC, Siemens, Heidenhain…).

Thanks to the integration of NCSIMUL Tool database, NCSIMUL CAM provides a direct access to 3D tool data and cutting conditions and automatically reconfigures the tool magazine.

This will provide manufacturers with the level of flexibility they need to achieve rapid switching of scheduled production from one CNC machine to another, making their production means fully flexible and agile.

- “Hybrid” programming, taking the pain out of legacy re-use,

- Error-free programming in native NC code, for an all-in-one solution,

- No more external post-processor, streamlining the CAM process,

- One-click re-programming, for complete flexibility,

- Dynamic management of intermediary rough stocks for unrivalled programming comfort

The company's new product delivers agile and native CNC programming to streamline the current serial and iterative CAM process and provides unparalleled flexibility on the shop floor. NCSIMUL CAM directly generates verified and optimized CNC programs, while factoring in the physical resources available on the shop floor, including tools, cutting conditions, kinematics and machine controllers.

NCSIMUL SOLUTIONS V10 is more than just a new version: a technological milestone for manufacturing and production in the aircraft industry– unique and simple to operate. It facilitates a comprehensive, integrated control of the complete machining process, including: G-Code processing, G-code file simulation, Cutting and tool management, DNC G-code file management, Real time machine status monitoring, Technical content publication.

This unique approach, streamlining the complete end-to-end machining process, delivers the tools and flexibility required to build the Factory of the Future.

NCSIMUL CAM Product Overview

NCSIMUL CAM directly generates verified and optimized CNC programs, while factoring in the physical resources available on the shop floor, including tools, cutting conditions, kinematics and machine controllers.

With this new solution, CAM data (APT neutral file / CL-data) and existing CNC programs can be used easily to generate a valid new CNC program in just a few clicks for another machine using different kinematics and controller. This will enable manufacturers to quickly adapt their existing programs to new resources when retrofitting a machine, buying a new one or when a machining process is repurposed. With a conventional CAM process (CAM-Post-Processor-Machining Simulation), this task could take hours, even days. With NCSIMUL CAM, these times are slashed to minutes.

Likewise, if the target machine initially planned for the CAM program is no longer available for maintenance reasons or is already being used to meet production, it will take just one click with NCSIMUL CAM to switch programming to another machine – whatever its complexity (3X to 5X, 5X to 4X…), the type of kinematics (tilting head to table-on-table for instance) or the type of controller (FANUC, Siemens, Heidenhain…).

Thanks to the integration of NCSIMUL Tool database, NCSIMUL CAM provides a direct access to 3D tool data and cutting conditions and automatically reconfigures the tool magazine.

This will provide manufacturers with the level of flexibility they need to achieve rapid switching of scheduled production from one CNC machine to another, making their production means fully flexible and agile.

Five key features of NCSIMUL CAM

- “Hybrid” programming, taking the pain out of legacy re-use,

- Error-free programming in native NC code, for an all-in-one solution,

- No more external post-processor, streamlining the CAM process,

- One-click re-programming, for complete flexibility,

- Dynamic management of intermediary rough stocks for unrivalled programming comfort

For more details on SAEILO Japan click here

For more details on NCSIMUL CAM click here

SPRING Technologies announces the worldwide release of NCSIMUL CAM

NCSIMUL CAM, a new module for the NCSIMUL SOLUTIONS 10 platform, is now available on demand via the ncsimul.com website

SPRING Technologies, vendor of software that optimizes the use of NC machines, announces the worldwide release of NCSIMUL CAM, the module that puts the finishing touch to existing CAM programs.

Based on CAM data inputs (CATIA®, NX®, CREO®, MASTERCAM®, and TOPSOLIDCAM®),

or existing NC programs (G-code format), NCSIMUL CAM directly generates verified and

optimized CNC programs without an external post-processor.

Ease of use and reliability were the watchwords in the development of NCSIMUL CAM, designed

to streamline digital processes across a wide range of industries including Aerospace,

Automotive/Transportation, Energy, and Medical instrumentation, where productivity and

competitiveness are at a premium.

With the unique new solution, businesses in these sectors have maximum flexibility when selecting machines for their workshops.

Six highlights of NCSIMUL CAM:

| - No more external post-processors, for a simplified NC process; - 1-click reprogramming, for complete flexibility; - “Hybrid” programming, for easy reuse of existing NC Data (g-code or CL-data inputs); - Programming in native NC code verified and optimized for an all-in-one solution; - Unique data file, to enable production to be transferred more smoothly from site to site; and - Dynamic management of intermediary rough stocks for unrivalled ease of programming. For the complete story click here |

Sunday, October 11, 2015

NEW | Create CNC machining reports in just a few clicks

Did you know ?

Did you know you can create your CNC machining report of every job produced for the shop floor in just a few clicks?

If you are using regular Office tools to gather tooling information and screenshots to prepare your shop floor documentation, it can take hours. However, this long and tedious process can be rectified.

With NCDoc, add-on of NCSIMUL Machine, you can automatically generate all information already available from the verification and CAM.

Discover in less than 90 seconds how to significantly shorten documentation time on your schedule ... with NCDoc!

| NCSIMUL Machine | CNC realistic simulation As a leading industry standard, our CNC simulation solution helps you save time, money and machine. |

Thursday, October 1, 2015

SPRING Technologies is exhibiting at the EMO tradeshow

SPRING Technologies is exhibiting at the EMO tradeshow, Hall 14 booth N19, with SMP, and be also present at Zoller and +GF+ booths to demonstrate NCSIMUL MACHINE and NCSIMUL CAM

SPRING's exhibit will highlight the latest features, benefits, and applications of company's flagship simulation module, NCSIMUL Machine and its latest module NCSIMUL CAM, on SMP booth - Hall 14, N19.

You can also come to visit us :

- Zoller booth - Hall 6 L18 M13 - to discover the new features, as well as attend the daily NCSIMUL CAM live presentations, from 2.00 to 2.30pm

- +GF+ booth - Hall 9 C06 - where NCSIMUL MACHINE will be daily demonstrated through a 20 minutes live presentation :

- Monday 05th | 03.00 pm

- Tuesday 06th | 03.30 pm

- Wednesday 7th | 02.30 pm

- Thursday 8th | 12.15 pm - 03.00 pm

- Friday 9th | 11.30 am - 04.00 pm

Location: Milan, Italy

Hall 14 booth N19

To see how the system functions and the benefits that can be realized, visit us during the EMO tradeshow.

Luc WERQUIN | +33 (0)1 43 60 25 23 | lwerquin @ ncsimul.com

Subscribe to:

Comments (Atom)