This past month, SPRING Technologies

participated in a 2-day NCSIMUL training organized and performed by re-seller,

Cognisco Technologies Inc. which was hosted by the Wentworth Institute of

Technology where educators of various academic

institutions explored the benefits NCSIMUL can offer for

manufacturing programs in trades and Higher Education.

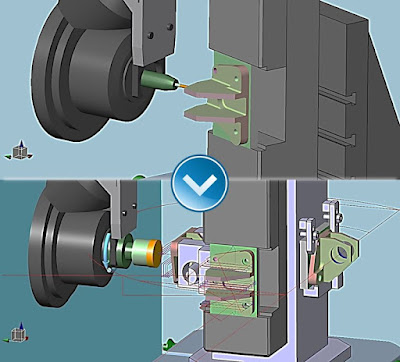

Due to NCSIMUL Machine's

ease-of-use, power, and myriad of features, attendees expressed the flexibility

that this unique virtual machining environment offers in a classroom

setting. These factors include: accessibility; NCSIMUL is Windows/PC compatible

and can be downloaded directly on a student's PC. It only requires a short

training and students can conveniently write their own manual G-Code, test

their CAM posted outputs and visualize projects in record time. NCSimul can

also be supplied with optional 4 and 5 axis CNC machines, which allows more

possibilities to have students extend and improve their programming skills without fear of damaging expensive equipment.

During this training, educators discovered how NCSIMUL can save them hours in reviewing student's codes and

grading projects, and as a result, how it lends them more time for teaching.

This is owing to NCSIMUL’s capacity to instantly show syntax erros, to simulate

the machining in one click to immediately locate any collisions and machining

mishaps, and compare the machined part to the original part and spot design

errors. Educators can have students build their own machines, tools

libraries, and create a variety of exercises for them that range from simple to

complex that will foster innovation in the classroom.

For more information on how your precision machining academic program can benefit from NCSIMUL’s power and user friendliness, please directly contact info@cogniscotech.com.